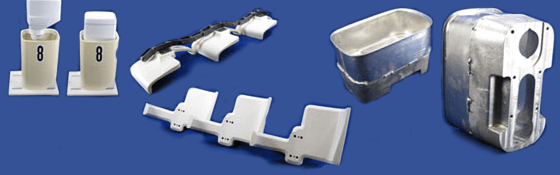

Assembly Fixtures

IMPM’s skilled pattern-makers are able to build fixture patterns from your production parts. This hand-done process may seem outdated compared to modern CNC machining, but CAD systems cannot accurately estimate the tolerances and non-uniform shrink that comes from a true molded or cast part. When an assembly fixture is built from the finished product, the fixture will support 100% of the areas of your choice.

IMPM has the ability to create assembly fixtures that will improve the efficiency of your assembly line. Our fixtures are designed and engineered to your particular assembly applications.

Our No-Mar assembly fixtures can be made to your hardness requirements based on your application whether it is screwing, tapping, or sonic welding.

Material Handling Fixtures

IMPM has worked extensively for the plastic container industry in providing material handling fixtures. These fixtures can be created in a variety of ways including machining, cast aluminum, vacuum forming and molded plastic.

Bottle Masks

IMPM knows that high quality parts ensure customer satisfaction. That’s why we have been supplying bottle masks to Quality Assurance Managers for years. These masks are vacuum formed from a supplied bottle to fit snug for testing wall thickness and ensuring conformity throughout a production line.