SLA (stereolithography) is the most accurate rapid prototyping / 3D printing technology in the manufacturing industry today, and IMPM is using some of the newest SLA technology on the market. We are currently running two different machines: the Uniontech RS Pro 800 and the ProJet 7000®. The ProJet 7000 has a 15″ x 15″ x 10″ build platform capacity; this machine also has the option to build in High Definition to produce extra fine detail. The Uniontech RS Pro 800 has a 31″ x 31″ x 21″ build platform; this build platform is one of the largest platform capacities amongst SLA printers, which makes it perfect for larger models. While every machine has it platform capacity, IMPM does limit model size to machine size; models with geometry larger than the extents of the build platforms can be built in sections, and then adhered together. Both machines print in .004″ layer resolution, providing you with the highest quality parts.

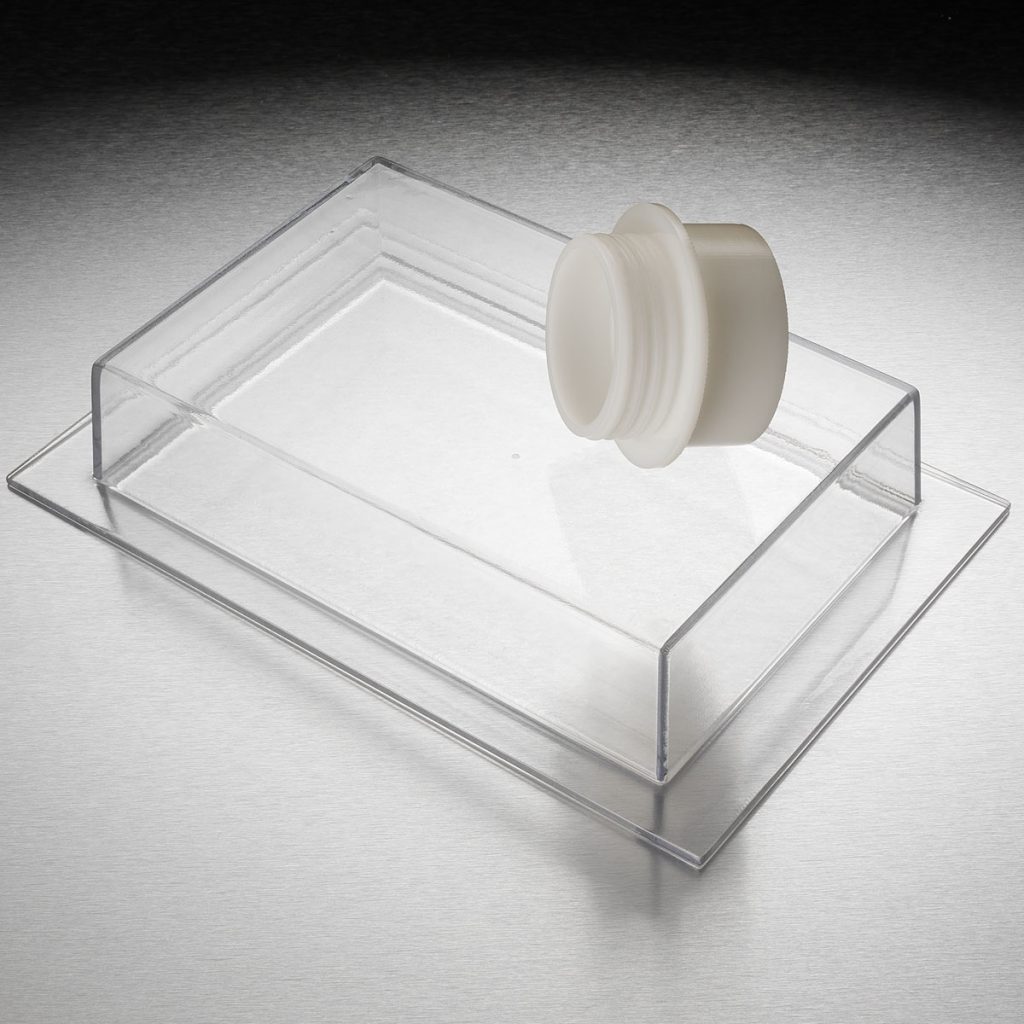

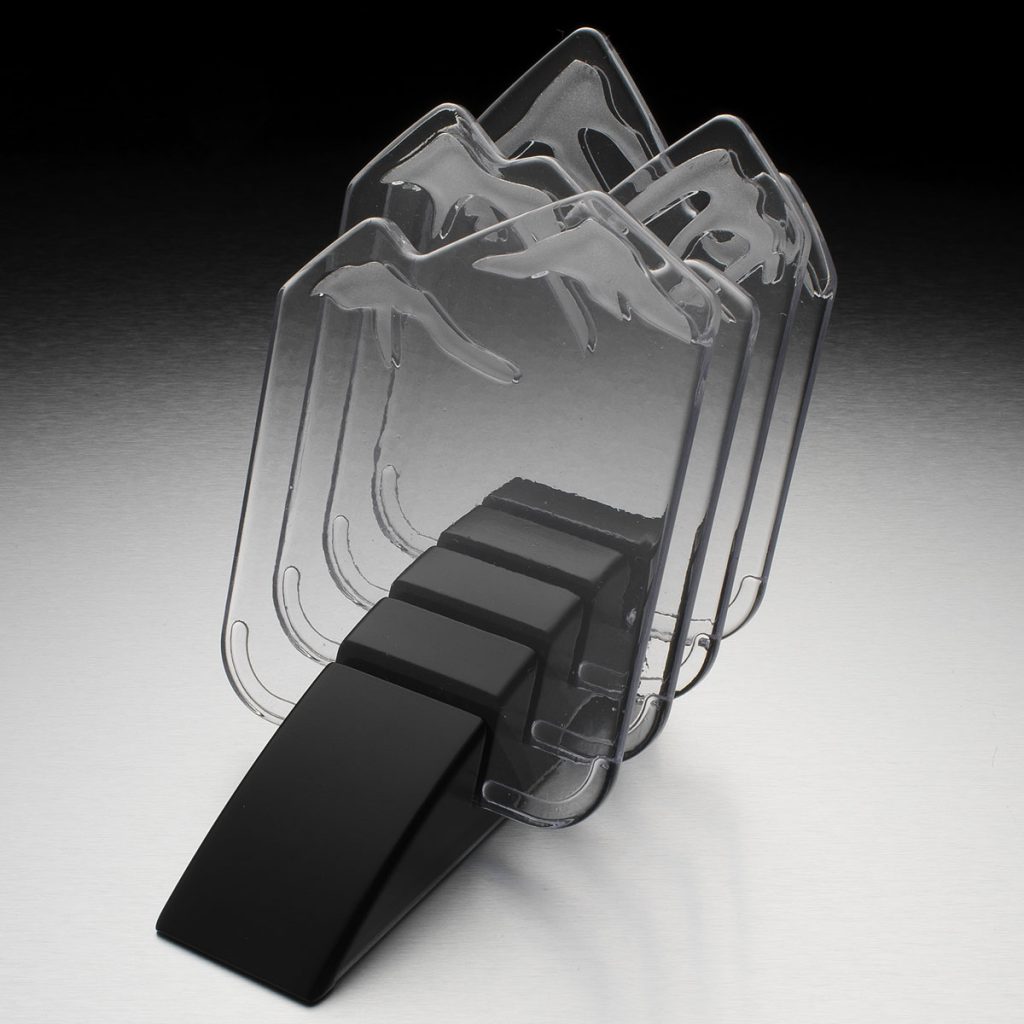

The ProJet 7000 uses Accura Clearvue resin for a stiff, durable, polycarbonate-like look and feel with a crystal-clear appearance that is ideal for “see-thru” applications. The material can be sanded and clear coated to near glass-like transparency, as well as diffused translucency. The Uniontech RS Pro 800 uses Somos® EvoLVe 128, a durable stereolithography material that produces accurate, high-detailed parts, and has been designed for easy finishing. It has a look and feel that is almost indistinguishable from finished traditional thermoplastics, making it perfect for building parts and prototypes for functional testing applications – resulting in time, money and material savings during product development. Somos® EvoLVe 128 is an outstanding material for industries such as aerospace, automotive, medical, consumer products and electronics.

SLA model finishing options include various sanding levels, various transparencies, single color painting, and custom paint jobs. We can match paint based on Pantone® number, various color codes, or any physical sample that is provided to IMPM.

Most SLA models can be shipped next day.

Benefits and Applications of SLA 3D Printing

- Accurate models for proof of concept and models with a high aesthetic priority

- Accurate masters for silicone tooling

- Fast build times

- Inexpensive

- Exemplifies fit, feel, and form of design

- Produces finest detail amongst 3D printing technologies

- Various material options

SLA 3D Printing at IMPM

- Newest SLA technology on the market

- Build platform as large as 31.5” x 31.5” 21.6”

- Material choice of Accura CLearVue or Somos EvoLVe 128

- Standard layer thickness of .004”

- High definition layer thickness of .002”

- Custom finishing options

- Quick quoting and build turnaround

- Most accurate masters for industry leading in-house silicone tooling

Read more about IMPM’s SLA material properties and part finishing options